Redthane Vee Belting RB10-2

Product code: RB10-2

Redthane Vee Belting has proved itself to be an exciting development in the field of mechanical power transmission, both in terms of reliability and cost saving.

Mackay Polyurethane Vee Belting – it’s so different it really saves money!

FEATURES:

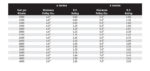

• Replaces almost all types of conventional belting, i.e. A,M and B section vee belts, link belting and all round-section belts.

• Precision manufactured in the form of a Polyurethane based tube offering unique qualities of strength, durability, resistance to oils and abrasion, moisture, radiation and chemicals.

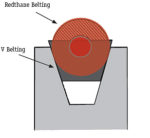

• Supplied in a continuous length. Required length is simply cut off and fastened internally (as illustrated) to give smooth, trouble free running. No motor/pulley adjustments are necessary before or after fitting.

• Reduces fitting time dramatically e.g. conventional belting on a Holbrook Centre Lathe – 155 minutes; RVB – 20 minutes. Crucial savings in terms of machine down time, direct labour, production losses etc.

• Cuts belt wastage to a minimum. When just one portion of the belt is damaged, that portion can be cut and replaced with a new section. No question of scrapping the whole belt.

• Provides the complete answer where stocks are concerned. Instead of having to stock up with countless different vee belts, just one or more RVB coils will supply all your needs with the minimum of time and space taken up.

THE MAXIMUM OPERATING TEMPERATURE FOR REDTHANE IS 80 DEGREES CELSIUS.

HOW TO MAKE ENDLESS REDTHANE BELTING

Using the Patented Internal Fastener:

This method can be carried out on the machine if necessary.

1. Check the length of the belting required, reduce the measurement by 7% (70mm per metre) and cut.

2. Using long nose pliers, insert the fastener into the tube at an angle and “walk” it in until the fastener is completely home, taking care NOT to damage the flange.

3. Insert the other end of the fastener into the tube’s other bore and using the same principle as before, fit it in to form an endless belt.

4. Stretch onto the pulleys.

Using Heat Welding:1. Cut the belt 7% shorter than required, making sure the ends are square and flat.

2. Heat a flat element to 300°C (+/- 40 °C).

3. Press both ends of the belt onto the element and melt back 1mm.

4. Press the melted ends together squarely (a V block can be used as a guide) and hold firmly for about 1 minute. Do not squeeze the molten Redthane away from the joining faces.

5. Cool thoroughly.

6. Trim off the surplus material around the joint using a sharp knife or grinding wheel.

7. Wait five minutes before stretching the belt over the pulleys.

Redthane belting is generally considered non-toxic, but has not been approved by the U.K. Drug and Food Administration.

| D - Diameter | 10.2mm |